Welding and Services

How We Support Our Manufacturers

High Volume Welded Assemblies

Manufacturers around the world rely on precision welding for many different applications, especially when it comes to constructing heavy equipment and machinery. Precision welding involves fusing together two pieces of metal with extreme accuracy, which requires incredibly high levels of skill and precision from the welder, as well as the tools that he or she uses to perform the welding process.

High Volume Manufacturing

For high-volume manufacturers who have production lines that run constantly at high speeds, having a partner that can also develop products with high-volume efficiency. For this reason, precision welding plays a vital role in ensuring high-quality products are produced on a consistent basis and is essential for protecting productivity while maintaining efficient production times.

Large Weldments

A large weldment, or a weldment that is simply large relative to other weldments and objects within its environment, can be difficult for an inexperienced welder because it often requires more skill and precision than normal welding procedures. At Big Gun Robotics, our welders utilize precision welding and skilled training to handle any project.

What We do

Big Gun Robotics is here to help manufacturers of all types to keep their lines moving and their supply chain working at its top level. With years of experience and a high focus on quality and in-time services, our team can help keep your company running its best.

Robotic Welding

At Big Gun Robotics, we have robotic cells differing several different axis that can get to parts many others can’t. By automating this process, we can get high-quality welds on most products up to three times faster than other weld shops.

Hand Welding

Some parts are still welded by hand, but we have the resources and expertise to deliver no matter what the project looks like. At Big Gun Robotics we have 20 manual weld stations producing weldments to exact customer specifications.

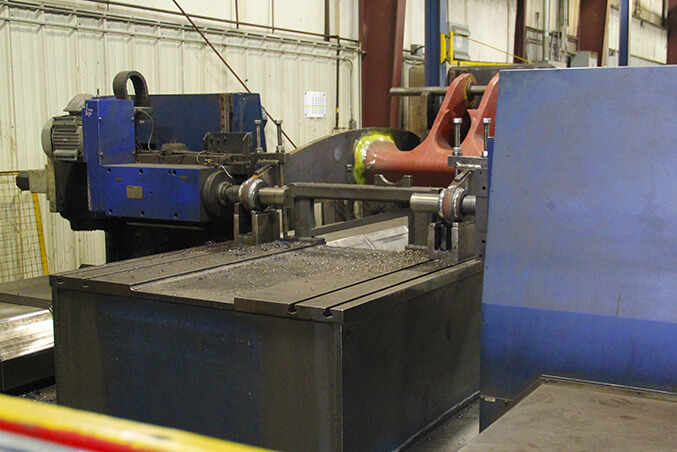

Inline Boring

After the weld, we can help with inline boring, creating perfectly concentric bores with tolerances up to a length of 12 feet. In addition to that, we can add bore welding to needed areas, adding additional metal that can be machined back to the correct size and specification.

Tight Tolerance Adherence

Within our industry that is focused on niche and heavy equipment, Big Gun Robotics has the ability to perform all of our services to a tight customer specification tolerance. Not only do we consider our program to be of the highest quality but we also adhere to safety protocols and industry standards.

Painting

With a blast room that allows us to take on many different project sizes, Big Gun Robotics offers prep and painting to get each part to a finished state without ever leaving our facility. With two paint booths, we can process heavy high volume with quick throughput, we can get your pieces primed, prepped, and painted in no time at all.